PRODUCT CATEGORY:

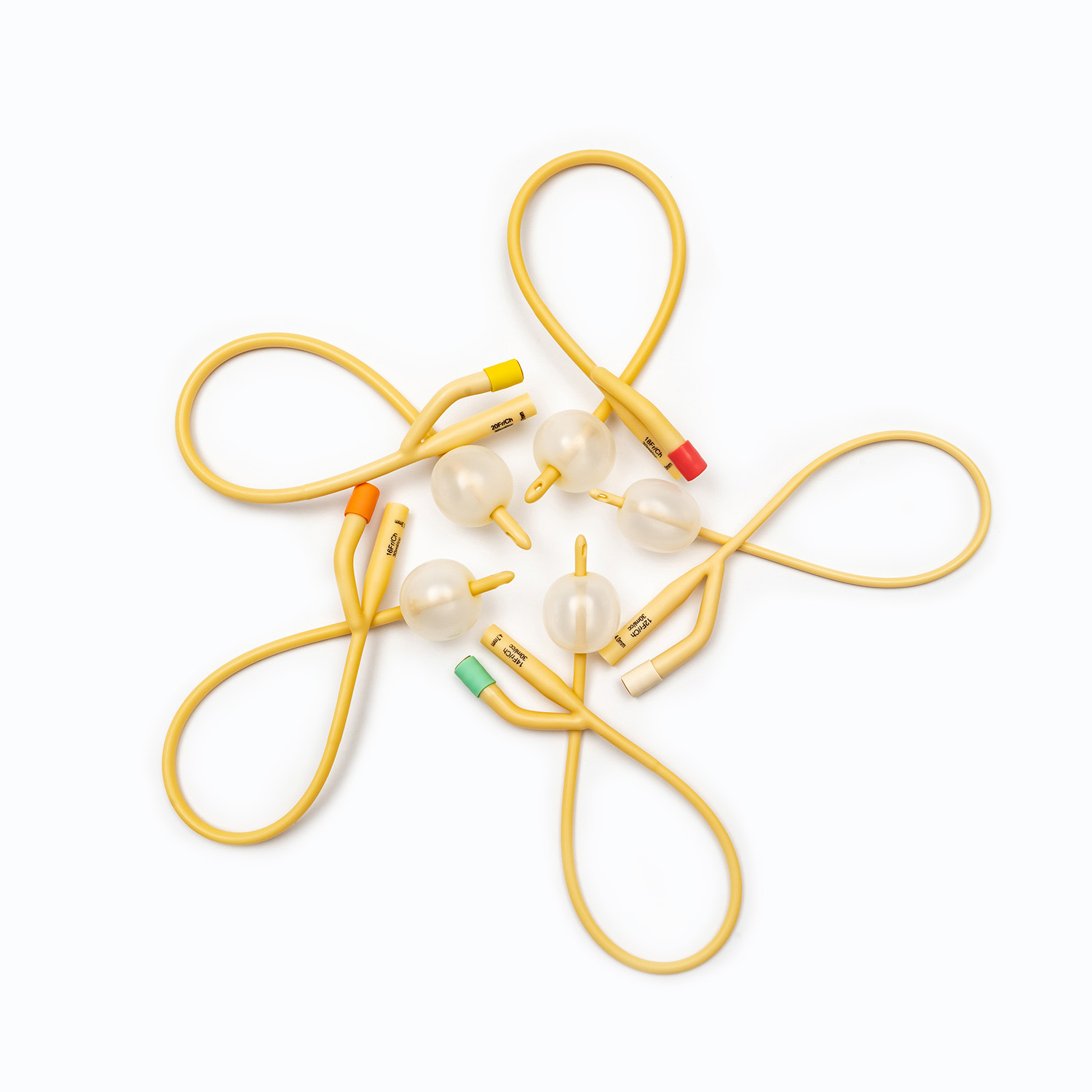

Disposable Double Lumen Latex Catheter Urinary Catheter/Drainage

Size: 6Fr/ch-30Fr/ch

Package: PE bag or Blister bag

Material: Natural latex

Description:

A dual-lumen latex catheter is a catheter made of latex that has two separate chambers. This type of catheter is often used in special circumstances, such as when urine needs to be directed and medications or lubricants need to be administered at the same time.

The features and functions of the double-lumen latex catheter are as follows:

1. Two independent chambers: Double-lumen latex catheters have two independent tubes, one for guiding the flow of urine and the other for instilling medications or lubricants. This allows for convenient urine elimination and other therapeutic procedures.

2. Labeling: The two chambers of a urinary catheter are usually individually labeled to help the doctor or nurse identify the function and purpose of each chamber.

3. Balloon: The end of the double-lumen latex catheter containing the drainage cavity is usually equipped with an inflatable balloon to fix the catheter and prevent it from prolapse. The perfusion chamber usually does not have a balloon.

4. Scope of application: Double-lumen latex catheter is suitable for situations where urine guidance and treatment need to be performed at the same time, such as urethral stricture treatment, drug infusion, etc.

-

Floor Area

0m² -

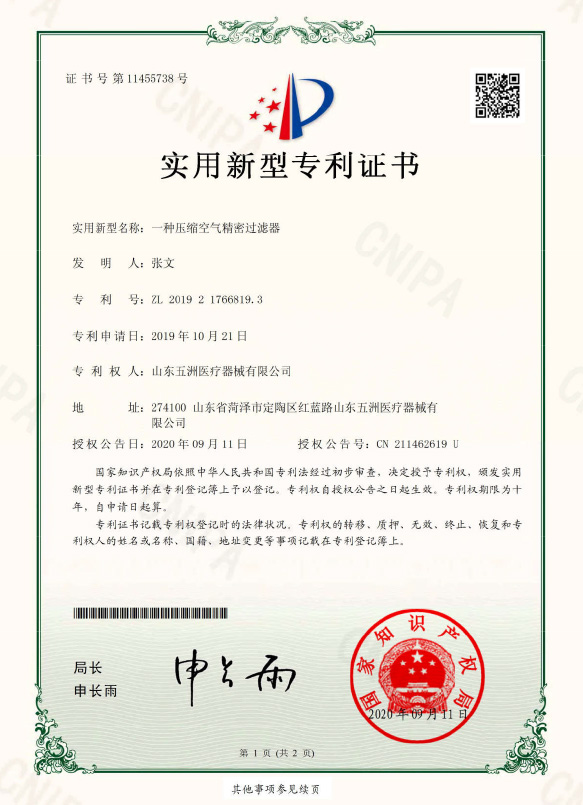

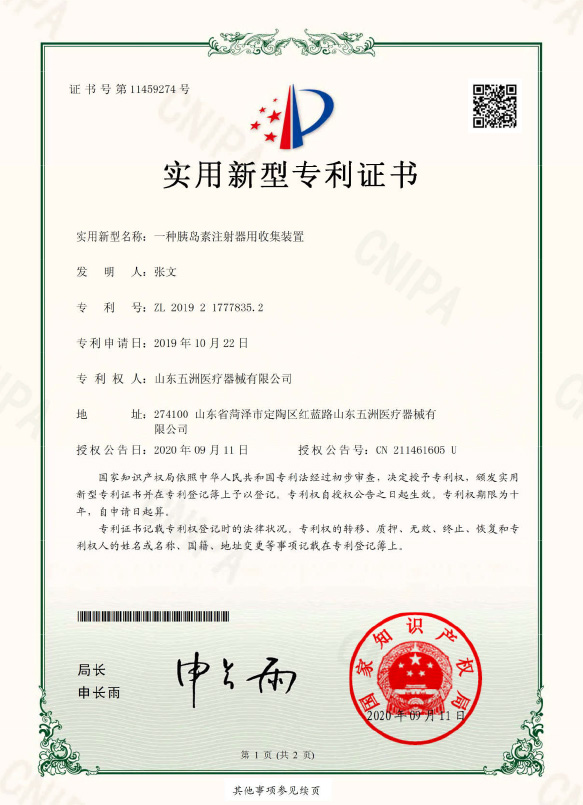

Patent Certificate

0 -

Employees

0+

-

Dec 22,2025 - Posted Admin

With the continuous advancement of medical technology, intravenous infusion therapy has become one of the comm...READ MORE + -

Dec 15,2025 - Posted Admin

In modern dental treatment, the effectiveness of anesthesia directly impacts the smoothness of the doctor's pr...READ MORE + -

Dec 08,2025 - Posted Admin

Introduction In modern diabetes management, the insulin syringe has become an indispensable basic instrument f...READ MORE + -

Dec 01,2025 - Posted Admin

In modern medical practice, blood transfusion has become a crucial life-saving procedure, and the blood transf...READ MORE + -

Nov 22,2025 - Posted Admin

In modern healthcare systems, intravenous infusion therapy is an indispensable part of clinical practice. As a...READ MORE + -

Nov 15,2025 - Posted Admin

Urinary catheters play a vital role in modern healthcare. They not only provide patients with a safe and conve...READ MORE +

Our mission is to offer "High Quality" & "Good Service" & "Fast Delivery'to help our clients to gain more profits.

What are the basic steps in latex catheter manufacturing?

Latex catheters are a common medical device used to deliver liquids or gases, such as IV tubes, ventilator tubes, etc. The basic steps for manufacturing latex catheters usually include raw material preparation, mixing, extrusion, vulcanization, testing and packaging. Below is a detailed description of these steps:

Raw material preparation:

The first step in making latex catheters is to prepare the raw materials. The main raw materials include latex, plasticizers, vulcanizing agents, antioxidants, fillers, etc. The selection and quality of these raw materials directly affects the performance and durability of the final latex catheter.

Mixing:

Mixing is usually performed on a dedicated mixer. A mixer is usually a huge reactor with a stirrer inside to thoroughly mix the raw materials. The design and movement of the agitator have an important impact on the mixing effect. According to the formulated formula, various raw materials weighed in advance are accurately put into the mixing machine. Formula accuracy and control are key factors in ensuring product quality. Once the raw materials are placed into the mixer, the heating process begins. The purpose of heating is to make the latex fluid and facilitate mixing. Steam or electric heating systems are usually used, and temperature control is very critical to ensure that the mixing temperature is within the appropriate range. While heating, the mixer's agitator starts working, mixing the raw materials with each other. This process takes some time to ensure that the ingredients are fully integrated to form a homogeneous latex mixture. The mixing time and speed are also parameters that need to be precisely controlled, followed by cold zone and sampling testing.

Extrude:

The kneaded latex mixture is fed into the extruder. An extruder mechanically squeezes latex into a tube or specific shape, a process called extrusion. The design and adjustment of the extruder affects the diameter, wall thickness and other parameters of the tube.

vulcanization:

The extruded latex catheter is vulcanized, a critical step. The purpose of vulcanization is to chemically react with the vulcanizing agent in the latex through heating to form the elastic skeleton of the latex catheter. The time and temperature of the vulcanization process will affect the hardness and elasticity of the conduit.

Cooling and dressing:

The vulcanized latex conduits are fed into a cooling unit to solidify them. At the same time, trimming and cutting are performed to ensure that the size, shape and surface quality of the conduit meet standards.

Detection:

Manufactured latex catheters need to undergo strict testing to ensure product quality. Common inspections include appearance inspection, dimensional measurement, hardness testing, tensile strength testing, etc. These tests ensure the reliability and safety of the catheter.

Cleaning and packaging:

Latex catheters that have passed the inspection need to go through a cleaning process to ensure that their surfaces are clean and dust-free. This is followed by packaging, usually in sterile packaging to prevent contamination and preserve the long-term shelf life of the product.

The manufacture of latex catheters involves several key steps, including raw material preparation, compounding, extrusion, vulcanization, testing and packaging. Precise control and quality monitoring of each step are important links to ensure that the final product meets medical standards and safety requirements. The successful execution of these steps not only affects the physical properties of the catheter, but also relates to its effectiveness and safety in the medical field.

English

English Français

Français русский

русский Español

Español